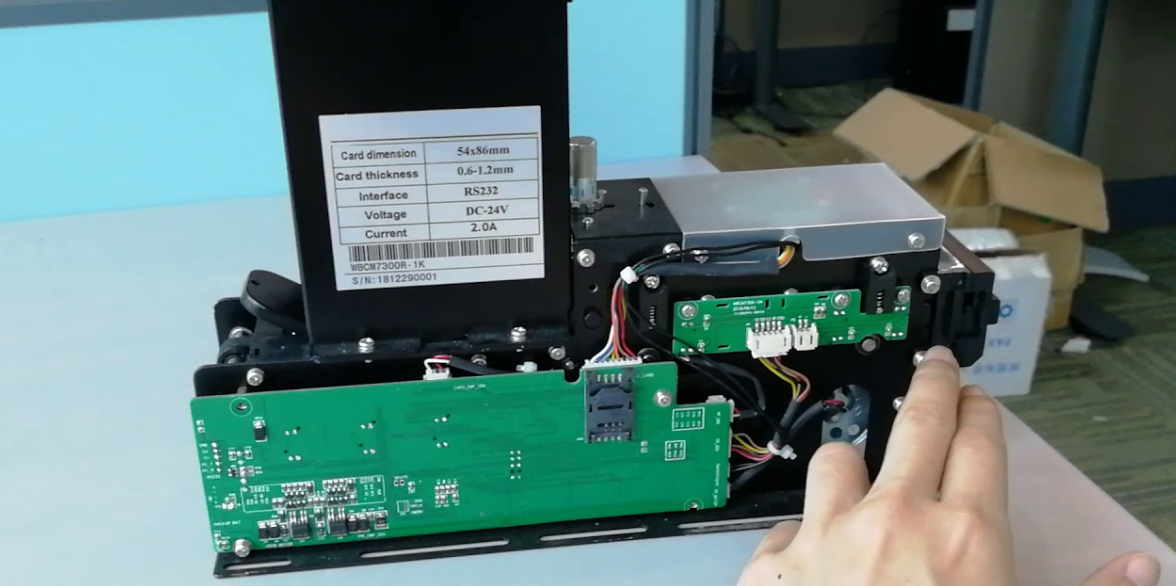

The process of using a computer device to produce a solid shape is called aerospace cnc machining. This device helps you produce the desired prototypes. Many industries use this technology to produce the desired products by giving digital instructions. There are three primary components of this technology and these are three primary components – a command function, a drive system, and a feedback system. It is a technology that uses plastic, metals, aluminum, etc. to create different shapes. CNC machines are used worldwide due to their ample benefits and easy use. In this article, you will learn everything about CNC machines and their features, and their usage in detail.

Features Of Aerospace CNC Machining

1. Superior Performance

Aerospace CNC machining helps manufacturers to produce products of high quality because aerospace components work only if its requirement of dimensions, high performance, and tolerable environment are fulfilled.

2. Light Weight

Aerospace equipment requires them to be lightweight as they have to take flight. CNC machining produces thin wall products. These products are thin, yet strong to fulfill the requirements.

3. High Efficiency

If the manufacturing company has one CNC machine, several machining processes can be done. Automation gives the machine extra strength and speed to decrease the time of production and improve efficiency.

4. Reliable Accuracy

With the advanced technology, the CNC machine is becoming more precise with every new launch. Better accuracy and control decrease manufacturing defects.

5. Affordable Price

Improved output enhances profits. High production also decreases costs and provides you the affordable products because the money is saved on labor costs, defects, and material waste.

Where Is Aerospace CNC Machining Technology Used?

There are many uses of aerospace CNC machining technology. The components that are produced through CNC machining technology are less expensive and easy to handle.

- Seats: Seats take up a lot of weight in aerospace, so it is necessary to use lightweight materials like aluminum to make sturdy seats.

- Shafts: Shafts are important for power transfer in aerospace applications. This technology can produce strong parts using materials resistant to heat.

- Oxygen Generation Components: CNC machining can help in producing the components that are used in oxygen generation.

- Valve Components: CNC machines are precise and produce the right sized and highly efficient valve components.

- Electrical Components: Electrical components are important for aerospace based on their lightweight and less space occupancy.

- Missile Housings: The outer case of the missile needs light weight material. CNC machining produces thin yet strong products and that is why used to produce missile housings.

Go With The Best In The Market

Aresprototype

Aresprototype is the brand that is the best brand for aerospace CNC machine technology. You can rely on them because they have years of experience in this field. Other technologies like rapid tooling, die casting and metal pressing are also popular in Aresprototype. They produce high-quality materials to ensure a safe and easy installation for aerospace. Their extensive client services quickly help you even if you have a small enterprise or the large enterprise. They are the best in the market because they use advanced technology to produce every product and their machines are known for their high accuracy and precision.

Conclusion

Aresprototype is the best brand to go for due to its ample benefits and affordable range. A huge number of customers have benefitted from their best products and you can also be one of them. Aerospace needs highly accurate components to ensure safety, and Aresprototype is the one that makes its products with utmost care and precision.